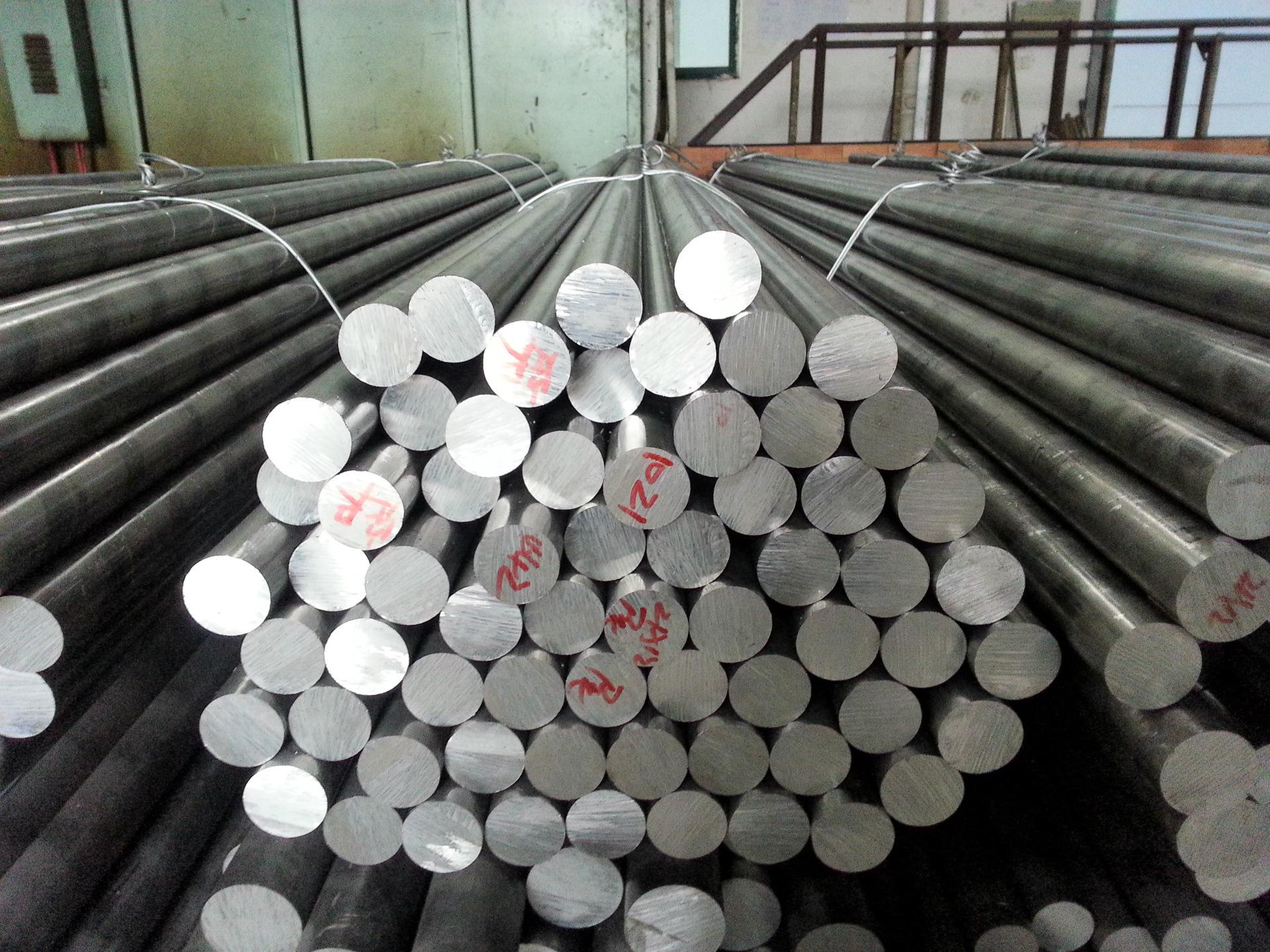

5454 aluminum square bar is lower magnesium content than alloy 5083, and as such is suitable for elevated temperature applications., which is widely used for petroleum and chemical industries.

Product advantages of 5454 aluminum square bar:

1. Accuracy:+/-0.02mm

Purpose: to guarantee the automatic processing of high precision machining parts.

2. Straightness <0.3m/2.5m

Purpose: Guarantee the speed requirements>8000 rpm, no material jittery.

3. Coarse crystal ring<0.5mm

Purpose: To reduce the amount of turning by the customer, improve efficiency and reduce costs.

4. Grain control

Purpose: to ensure that the 2、5、6、7 series aluminum alloy in the hard anodizing, anodizing uniform, color bright and beautiful.

5. Turning performance improvement

To improve the processing of uniform chip, improve the processing of yards yield.

Chalco Aluminium stocks a variety of aluminum alloy bars (rods) grades and sizes tailored to your needs and specifications.

|

Extruded Aluminum |

Al-Alloy | Temper | Stretching Test |

Hardness HB |

Temper | We Are Able To Produce Sizes Of | ||||||

|

Tensile Strength Rm/Mpa |

Yield Strength Rp0.2/Mpa |

Elongation A% |

OD | ID | Diagonal | A/F | Length | |||||

|

aluminum square bar |

5454 | H112 | >215 | >85 | >12 | 55 |

H111 H112 H32 H34 F |

3mm~ 130mm |

3mm~ 100mm |

3mm~ 130mm |

5mm~ 112mm |

1000mm~ 6000mm |

| O | 215-285 | >85 | >14 | 40 | ||||||||

| Annealing | TO | |||||||

| Hot work | T1 | H111 | H112 | |||||

| Cold work | H12 | H14 | H16 | H18 | H32 | H34 | H116 | H321 |

| Heat treatment | T3 | T4 | T5 | T6 | T8 | |||

| Over aging treatment | T73 | T74 | T76 | T79 | ||||

| Stress relieved | T351 | T451 | T651 | T7351 | T7451 | T7651 | T7951 | T851 |

5052 round aluminum bar rod billet has good weldability which is stronger than 5005 alloy and is wide...

5754 aluminum angle bar is with high mechanical resistance very easy to weld using conventional metho...

5083 aluminum square bar has highest mechanical properties of Mg-containing alloys low operating temp...

2014 round aluminum bar rod billets has high mechanical properties excellent resistance to fatigue go...