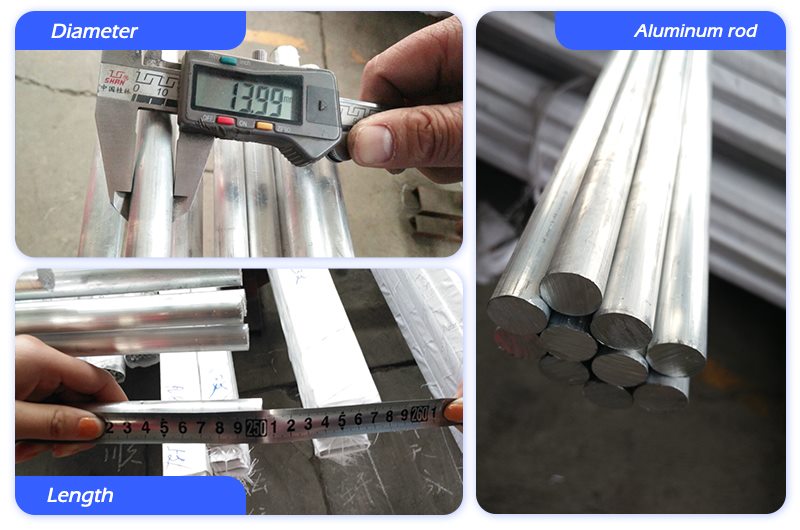

2195 high strength Al Cu alloy has high strength, good low temperature and high temperature characteristics, excellent welding performance, but poor corrosion performance. Used for propeller and magnetic barrel. 2195 aluminum bar rod is an aluminum alloy with copper as the main alloy element. 2195 aluminum alloy, American wrought aluminum and aluminum alloy. 2195 aluminum alloy has poor corrosion resistance and good machinability; Poor brazing, easy to arc welding and spot welding. It is suitable for structural parts and high-strength weldments working at 315 ℃. 2195 aluminum alloy is mainly used for aerospace rocket welding oxidant tank, supersonic aircraft skin and structural parts. Good weldability, high fracture toughness, and high stress corrosion cracking resistance in T8 state.

2195 aluminum alloy bar rod belongs to heat treatable and strengthened deformed aluminum alloy. After solution aging treatment, the mechanical properties of aluminum alloy have been greatly improved. Plastic deformation is accompanied by deformation strengthening of aluminum alloy. 2195 aluminum alloy is mainly used in the production of melon flap structure of aerospace rocket fuel storage tank in China. The scraping parts are mainly formed by drawing large aluminum alloy bars.

Temper of 2195 aluminum bar rod: O, T31, t351, T37, T42, T62, T81, t851, T87

Common status: O, t351, t851

2195 aluminum alloy with copper as the main alloy element.

Alloy state: the state of artificial aging after T4 solution treatment

It is applicable to products that are no longer subject to cold processing and artificial aging after solution heat treatment

Application: space rocket welding oxidant tank, supersonic aircraft skin and structural parts, working temperature - 270 ° C to 300 ° C. Good weldability, high fracture toughness, and high stress corrosion cracking resistance in T8 state.

2195 high strength Al Cu alloy has high strength, good low temperature and high temperature characteristics, excellent welding performance, but poor corrosion performance. Used for propeller and magnetic barrel. Application: space rocket welding oxidant tank, supersonic aircraft skin and structural parts, working temperature - 270 ° C to 300 ° C. Good weldability, high fracture toughness, and high stress corrosion cracking resistance in T8 state.

Aluminum-lithium alloy is the worlds lightest metal structural material with good thermal conductivity, electrical conductivity and ductility. It is mainly used in aerospace, defense and military industries, and exhibits in the fields of transportation, e...

We receive enquiries in English, Español (Spanish), Русский язык (Russian), Français (French) and العربية (Arabic).whether you are inquiring about the latest quotation of aluminum bars , or have any questions about aluminum rods, you can contact us ,our professional team will reply to you within one business day. Please feel free to contact us!

What is the 6063 t6 aluminum bar

6063 t6 aluminum bar containing magnesium, silicon, with excellent processin...+ Details

How can aluminum round bars be treated for anticorrosion?

The corrosion behavior of 6063 aluminum round bar caused by silicon can be c...+ Details

How much is a ton of aluminum bar?

Aluminum bars have a wide range of applications and many industries are inse...+ Details