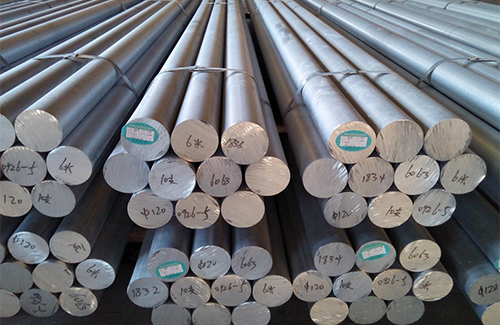

2A04 aluminum alloy rod for rivet has high shear strength and heat resistance, and the pressure processing property, machinability and corrosion resistance are the same as 2A12, and the intergranular corrosion tendency is smaller than 2A12 at 150-250C. Heat treatment strengthening, riveting in the annealed and quenched state (2 to 6h, depending on the diameter of the rivet).

2A04 aluminum alloy rod’s chemical composition:

Silicon Si: 0.30 Iron Fe: 0.30 Copper Cu: 3.2-3.7 Magnesium Mg: 2.1-2.6 Zinc Zn: 0.10 Manganese Mn: 0.50-0.8, Titanium Ti: 0.05-0.40 铍Be: 0.001-0.01 Aluminum Al: Quantity Note: Single: 0.05; Total: 0.10

2A04 T4 aluminum alloy rod’s mechanical properties:

Shear strength τ (MPa): ≥ 275 Note: Natural aging to basic stable shear resistance after wire solution heat treatment. Specimen size: wire diameter ≤ 6.0

Heat treatment specification

1) Rapid annealing: heating 350 ~ 370 C; with the effective thickness of the material, the holding time is 30 ~ 120min; air or water cooled. 2) Quenching and aging: quenching 500 ~ 510 C, air cooling; natural aging room temperature 120h.

We receive enquiries in English, Español (Spanish), Русский язык (Russian), Français (French) and العربية (Arabic).whether you are inquiring about the latest quotation of aluminum bars , or have any questions about aluminum rods, you can contact us ,our professional team will reply to you within one business day. Please feel free to contact us!

What is the 6063 t6 aluminum bar

6063 t6 aluminum bar containing magnesium, silicon, with excellent processin...+ Details

How can aluminum round bars be treated for anticorrosion?

The corrosion behavior of 6063 aluminum round bar caused by silicon can be c...+ Details

How much is a ton of aluminum bar?

Aluminum bars have a wide range of applications and many industries are inse...+ Details