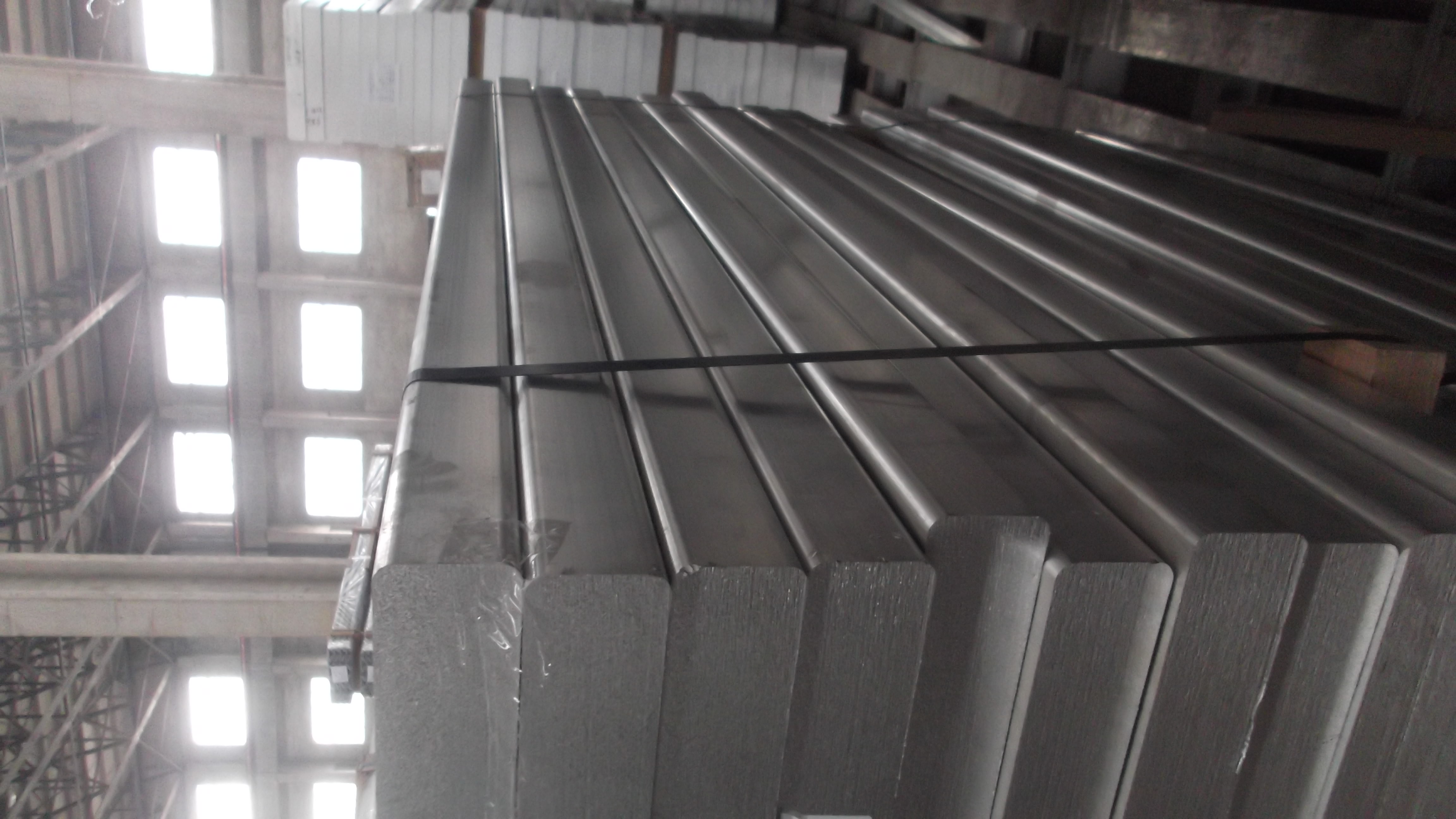

Production process of aluminum bar and aluminum profile

Aluminum bar Aluminum profile production process:

It mainly consists of three processes: casting, extrusion and coloring (mainly including oxidation, electrophoretic coating, fluorine carbon spraying, powder spraying, wood grain transfer printing, etc.).

1, melting and casting is the first process of aluminum production.

The main process is as follows:

(1) batching: according to the specific alloy grades produced according to the needs, the amount of all kinds of alloy components can be calculated and reasonably matched with all kinds of raw materials.

(2) smelting: melt the raw material into the melting furnace according to the technical requirements and remove the slag and gas in the melt effectively by degassing and slag refining.

(3) casting: the molten aluminum melted into a round casting rod of various specifications by deep casting system under certain casting conditions.

2, squeezing:

Extrusion is a means of forming a profile. First, according to the section design of the profile products, the mold is manufactured and extruded to form the heated round casting rod from the mold. The commonly used grade 6063 alloy is also used in the extrusion process, namely, the air cooling quenching process and the post artificial aging process to complete the heat treatment. The heat treatment systems of different grades of heat treated alloy are different.

3, color (first mainly the process of oxidation)

Oxidation: the extruded aluminum alloy profile, whose surface corrosion resistance is not strong, must be treated by anodic oxidation to increase the corrosion resistance, wear resistance and appearance of the aluminum. The high partition aluminum profiles produced by the Jane tall aluminum partition factory are almost all oxidized.

The main process is as follows:

(1) surface pretreatment: the surface of the profile is cleaned by chemical or physical methods, and the pure matrix is exposed, in order to obtain a complete and compact artificial oxide film. The mirror or matte (Ya Guang) surface can also be obtained by mechanical means.

(2) anodic oxidation: a surface pretreated profile, under certain technological conditions, the surface of the matrix is anodized to produce a layer of dense, porous and strong adsorptive AL203 film.

(3) sealing: the pores and pores of the porous oxide film formed after anodization are sealed, so that the oxidation resistance, corrosion resistance and wear resistance of the oxide film are enhanced. The oxide film is colorless and transparent. Using the strong adsorbability of the oxide film before sealing the hole, some metal salts are adsorbed and deposited in the membrane hole, which can make the profile appearance of the color (silver white), such as black, bronze, gold and stainless steel.

Chalco Aluminium is specialized in producing and marketing aluminium bar.Our customer service representatives are qualified,knowledgeable aluminum bars experts, Thire industry expertise and professionalism will save you time and money and ensure that you have the best aluminium bars and rods.

Inquiry

We receive enquiries in English, Español (Spanish), Русский язык (Russian), Français (French) and العربية (Arabic).whether you are inquiring about the latest quotation of aluminum bars , or have any questions about aluminum rods, you can contact us ,our professional team will reply to you within one business day. Please feel free to contact us!